1. What is SLA 3D Printer?

SLA (Stereolithography Apparatus) 3D Printer is a type of 3D printing technology. That uses a laser to cure liquid resin into solid plastic parts. SLA printers are capable of creating objects with very high resolution. Also, allows for intricate details and complex geometries. Yet, print much faster than other types of 3D printing. Thus, methods such as FDM (Fused Deposition Modeling) and SLM (Selective Laser Melting).

- 1. What is SLA 3D Printer?

- 2. How Does a SLA 3D Printer Work?

- 3. SLA 3D Printer Types

- 4. Choosing the Best SLA 3D Printer

- 5. Intamsys Funmat HT Enhanced 3D Printer

- 6. Fastest SLA 3D Printer

- 7. Largest SLA 3D Printer

- 8. SLA 3D Printer Price Range

- 9. High-Resolution SLA 3D Printer

- 10. SLA 3D Printer Kit

- 11. SLA 3D Printing Regulations

- 12. SLA 3D Printer File Format

- 13. SLA 3D Printer Materials

- 14. Conclusion

- FAQs

1.1. SLA 3D Printer Meaning

SLA stands for Stereolithography Apparatus, a type of 3D printing technology. That cures liquid resin with a laser to create solid plastic parts. These printers are capable of producing high and complex geometries. These have a high degree of accuracy and precision. But, applications such as jewelry, dentistry, and medical implants. Besides, it is a fast process compared to other types of 3D printing methods.

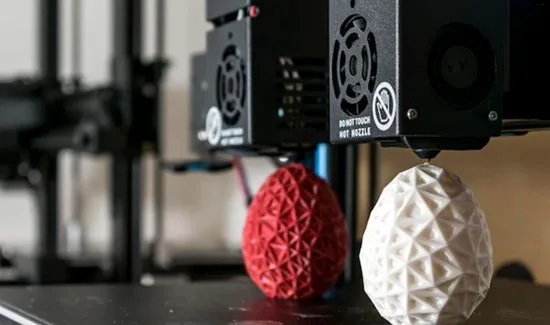

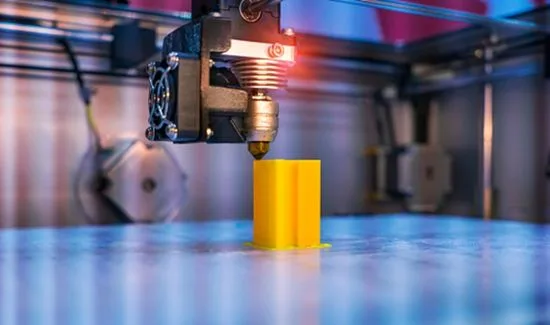

2. How Does a SLA 3D Printer Work?

SLA 3D Printers work by focusing a laser on the liquid resin to cure the material into solid plastic parts. The process begins with a liquid resin vat, which has a liquid polymer. SLA 3D printers have an ultraviolet laser. Thus, the laser beams on the resin scanned across the surface of the vat in a predetermined pattern. Also, the laser passes over the resin, solidifies, and out of the vat in a continuous stream. Yet, the process until the entire 3D object layer by layer from the bottom up.

3. SLA 3D Printer Types

SLA 3D Printers come in many different shapes and sizes. Desktop units to large industrial-grade machines. Depending on the size and type of printer, used to create objects such as acrylic, nylon, and rubber.

The most common SLA 3D Printer types include:

3.1. Desktop SLA Printers

Smaller, more affordable desktop SLA Printers are perfect. It’s hobbyists and small businesses. These units are more affordable than larger ones. It also has industrial-grade SLA 3D printers. It is suitable for creating smaller 3D-printed objects.

3.2. Industrial SLA Printers

Industrial-grade SLA printers are larger, more expensive machines. They are more complex 3D printing projects. These printers are in industrial settings. For instance, factories and research labs. Capable of producing larger and more intricate 3D-printed objects.

3.3. Resin 3D Printers

Also known as “DLP” printers, resin 3D printers are Like SLA 3D Printers. It uses a digital light projector instead of a laser to cure the resin. These printers are faster than SLA 3D Printers. It can produce detailed objects in a shorter amount of time.

4. Choosing the Best SLA 3D Printer

Choosing the best SLA 3D printer for your needs. Yet, it depends on a variety of factors, such as your budget, and the size and type of objects you want to create. . It’s important to do your research and compare different SLA 3D printers to meet your needs. Yet, if you’re looking for a more affordable option, you may want to consider a desktop SLA 3D Printer.

SLA 3D Printers solution for creating detailed and complex objects. With a high degree of accuracy and precision. Yet, if you’re looking for a desktop SLA 3D Printer or an industrial-grade machine. There are a variety of SLA 3D printers on the market to choose from. With the right 3D printer, you can take your 3D printing projects to the next level.

Here is a list of the Best SLA 3D Printers

4.1. Formlabs Form 3

Formlabs Form 3B is an industrial-grade SLA 3D Printer. They can build volumes and high-resolution printing capabilities. It features an efficient cooling system, and precise laser calorimetry. Variety of materials for printing objects with complex geometries.

4.2. Anycubic Photon S 3D Printer

The Anycubic Photon S is a powerful SLA 3D Printer that offers a large build volume. It has a dual rail XYZ system and a variety of materials to choose from. Equipped with an intuitive touchscreen interface, fast printing speeds, and built-in safety features.

4.3. Elegoo Mars Pro Mono MSLA 3D Printer

The Elegoo Mars Pro Mono MSLA 3D Printer is powerful and affordable. SLA 3D Printer that features a 6.08” x 4.72” x 5.5” build volume. Also has an LCD UV light source. Equipped with a variety of materials and features a simple design.

4.4. FlashForge Hunter DLP 3D Printer

The FlashForge Hunter DLP 3D Printer is a powerful resin. 3D Printer that features an XYZ resolution of 0.05mm and a 5” LCD screen. Designed for high-precision 3D printing. Capable of producing detailed objects in a matter of minutes.

4.5. Monoprice Mini SLA Resin Printer

The Monoprice Mini SLA Resin Printer 3D Printer offers an XY resolution of 0.05 mm. Builds a volume of 3.9” x 2.3” x 5.5”. They are for precision 3D printing. Yet, capable of producing detailed objects in a short amount of time.

4.6. XYZPrinting Nobel SLA LCD 3D Printer

The XYZPrinting Nobel SLA LCD 3D Printer is industrial-grade. SLA printer that features a large build volume. Yet, it also has a variety of materials for printing objects with complex geometries. Equipped with an intuitive touchscreen interface, fast printing speeds, and built-in safety features.

4.7. Phrozen Transform 3D Printer

The Phrozen Transform 3D Printer is a SLA printer that offers a large build volume and dual rail XYZ system. Yet, designed for precision 3D printing. Also, capable of producing detailed objects in a short amount of time. Also, it also features an intuitive touchscreen interface. Variety of materials for printing objects with complex geometries.

4.8. DAGOMA DiscoEasy 200 3D Printer

The DAGOMA DiscoEasy 200 3D Printer. SLA printer that offers a large build volume and a variety of materials. Equipped with an intuitive touchscreen interface, fast printing speeds, and built-in safety features. Also, it features a dual rail XYZ system. Also, capable of producing detailed objects in a short amount of time.

4.9. Peopoly Phenom 3D Printer

The Peopoly Phenom 3D Printer is industrial-grade. SLA printer that offers a large build volume. Variety of materials for printing objects with complex geometries. Equipped with an intuitive touchscreen interface, fast printing speeds, and built-in safety features. Besides, it features a dual rail XYZ system. Also, capable of producing detailed objects in a short amount of time.

4.10. X-Cube SLA 3D Printer

The X-Cube SLA 3D Printer is powerful and affordable. SLA 3D Printer that features a 6.08” x 4.72” x 5.5” build volume and an LCD UV light source. Designed for high-precision 3D printing. Capable of producing detailed objects in a matter of minutes. Also, it features an intuitive touchscreen interface. Variety of materials for printing objects with complex geometries.

4.11. Kudo3D Bean 3 SLA 3D Printer

The Kudo3D Bean 3 SLA 3D Printer is powerful and affordable. SLA 3D Printer that offers a large build volume and a variety of materials. Equipped with an intuitive touchscreen interface, fast printing speeds, and built-in safety features. Yet, it features a dual rail XYZ system and is capable of producing detailed objects in a short time.

4.12. XYZprinting Nobel 1.0 3D Printer

The XYZprinting Nobel 1.0 3D Printer is an industrial-grade. SLA printer that features a large build volume. Variety of materials for printing objects with complex geometries. Hence, equipped with an intuitive touchscreen interface. fast printing speeds, and built-in safety features. Also, it features a dual rail XYZ system. They are capable of producing detailed objects in a short amount of time.

4.13. Formlabs Form 2 3D Printer

The Formlabs Form 2 3D Printer is professional-grade. SLA printer that offers an XY resolution of 25 microns. It can build a volume of 145 x 145 x 175 mm. Designed for 3D printing and is capable of producing detailed objects in a short amount of time. Besides, it features an intuitive touchscreen interface. Variety of materials for printing objects with complex geometries.

5. Intamsys Funmat HT Enhanced 3D Printer

The Intamsys Funmat HT Enhanced 3D Printer is industrial-grade. SLA printer that offers a build volume of 330 x 240 x 300 m. Its XY resolution is 44 microns. Designed for 3D printing and is capable of producing detailed objects in a short amount of time. Thus, it features an intuitive touchscreen interface. Variety of materials for printing objects with complex geometries.

5.1. Zortrax Inkspire 3D Printer

The Zortrax Inkspire 3D Printer is an industrial-grade SLA printer. It features a build volume of 8.3 x 8.3 x 9.5 inches and an XY resolution of 25 microns. Designed for 3D printing and is capable of producing detailed objects in a short amount of time. Thus, it features an intuitive touchscreen interface. Variety of materials for printing objects with complex geometries.

5.2. MakeX M-One SLA 3D Printer

The MakeX M-One SLA 3D Printer is powerful and affordable. SLA 3D Printer that offers a build volume of 120 x 68 x 200 mm. Its XY resolution is 0.047 mm. The 3D printer is capable of producing h detailed objects in a short amount of time. Thus, features an intuitive touchscreen interface. variety of materials for printing. Equipped with a range of built-in safety features.

5.3. ZMorph VX 3D Printer

The ZMorph VX 3D Printer is a powerful and versatile 3D printer. It offers a build volume of 270 x 200 x 200 mm and an XY resolution of 20 micrometres. Designed for 3D printing and is capable of producing detailed objects in a short amount of time. Thus, features an intuitive touchscreen interface. variety of materials for printing. Equipped with a range of built-in safety features.

5.4. Anycubic Photon Mono X 3D Printer

The Anycubic Photon Mono X 3D Printer is affordable. SLA 3D Printer that offers a build volume of 115 x 65 x 155 mm. It’s an XY resolution of 0.0125 mm. Designed for 3D printing producing detailed objects in a short amount of time. Thus, features an intuitive touchscreen interface. variety of materials for printing. Equipped with a range of built-in safety features.

5.5. Formlabs Form 1+ 3D Printer

The Formlabs Form 1+ 3D Printer is professional-grade. SLA printer that offers an XY resolution of 25 microns. Moreover, Build a volume of 145 x 145 x 175 mm. 3D printing is capable of producing detailed objects in a short amount of time. Yet, the printer features an intuitive touchscreen interface. Variety of materials for printing.

5.6. XYZprinting Nobel Superfine SLA 3D Printer

The XYZprinting Nobel Superfine SLA 3D Printer is powerful and affordable. SLA 3D Printer that offers a build volume of 115 x 65 x 155 mm. Its XY resolution is 0.04mm. Designed for 3D printing objects in a short amount of time. Also, it features an intuitive touchscreen interface. Variety of materials for printing objects with complex geometries. Equipped with a range of features.

These are some of the best SLA 3D Printers on the market today.

Each of these SLA 3D Printers has its own unique set of capabilities and features. Compare different models to determine which one is fit for your needs.

For instance, if you’re looking to create smaller objects with high levels of detail. A desktop SLA 3D Printer likes the Formlabs Form 3. Thus, Anycubic Photon S might be the best option. Moreover, if you’re looking to create larger objects with complex designs. Look for industrial-grade SLA 3D Printers like the Formlabs Form 2. Yet, Intamsys Funmat HT Enhanced 3D Printer might be the better choice.

6. Fastest SLA 3D Printer

SLA 3D Printer is on the market today. Intamsys Funmat HT Enhanced 3D Printer. It has a print speed of up to 500 mm/s and an XY resolution of 50 microns. Ideal for creating detailed objects in a short amount of time.

7. Largest SLA 3D Printer

The largest SLA 3D Printer currently available is the Massivit 1800 Pro 3D Printer. This industrial-grade printer offers a build volume of 1800 x 800 x 850 mm. Ideal for producing large objects with intricate designs.

8. SLA 3D Printer Price Range

The price of SLA 3D Printers can range from a few hundred dollars to tens of thousands of dollars. The cost will depend on the type and size of the printer. Desktop models for around $500 to $1,500. Also, industrial-grade 3D printers can cost anywhere from $2,000 to $50,000 or more.

9. High-Resolution SLA 3D Printer

The highest resolution SLA 3D Printer currently available is the Formlabs Form 2. It has an XY resolution of 25 microns. It’s capable of producing detailed objects in a short amount of time.

10. SLA 3D Printer Kit

Above all, SLA 3D Printer kits are also available. These kits include all the necessary components to build a functional SLA printer. They are a great option for those who want to save money and build their own SLA printer from scratch.

11. SLA 3D Printing Regulations

Thus before purchasing an SLA 3D Printer. It is important to be aware of the regulations surrounding 3D printing. 3D printing while in others it is not. So be sure to check the regulations in your area before purchasing a 3D printer.

12. SLA 3D Printer File Format

SLA 3D Printers work best with .stl and .obj file formats. Besides, some SLA 3D printers can also work with other file formats such as .gcode, and .dxf.

13. SLA 3D Printer Materials

SLA 3D printers print a variety of materials including plastic, resin, metal, and even food. Each material will have a different set of settings and filaments.

14. Conclusion

SLA 3D printers are powerful machines capable of producing detailed objects. They come in a variety of sizes, shapes, and prices. Depending on the type of printer you buy you can print objects. Range of materials including plastic, resin, metal, and even food. Moreover, it is important to be aware of the regulations surrounding 3D printing. Compare models to determine which SLA 3D printer is the best fit for your needs.

With the right SLA 3D printer, you can create objects. Incredible detail in a fraction of the time it would take to create.

After that, why not give it a try? Surprised by the possibilities!

FAQs

Advantages of SLA

· 3D printing includes high accuracy and detail, the ability to produce complex shapes, and a wide range of materials.

· SLA prints often have a smoother surface finish than FDM prints, which can be beneficial for certain projects.

Disadvantages of SLA

· 3D printing includes a slower print time, a high cost of equipment and materials, the need for special maintenance and post-processing, and the use of hazardous materials.

· SLA prints can be quite fragile and may require additional support or reinforcements depending on the design.

· It is important to consider all of these factors before deciding which 3D printing method is best for your project.

SLA 3D printing can be used with different types of materials such as resins, plastics and rubbers. Depending on the type of material used, different properties such as strength and flexibility can be achieved. It is important to consider all the factors before deciding which material is best for your project.

Yes, you can leave an SLA 3D Printer unattended while it is working. It is typically safe to do so as most SLA 3D Printers have safety features that will turn the printer off if anything goes wrong.

However, you should always monitor the progress of your print to ensure that it is progressing as expected. It is also a good idea to take safety precautions such as placing the printer in a well-ventilated area, away from any flammable objects.

The best way to ensure that your SLA 3D Printer is safe and running properly is to follow the manufacturer’s specified instructions.

Yes, you can use an SLA 3D Printer to create large objects. However, it will take longer than printing smaller objects. Additionally, you should ensure that you have enough resin and space to accommodate the larger object.

When printing large objects, it is also important to ensure that there is adequate support material and that the printer can reach all areas of the object. For best results, you should follow the manufacturer’s instructions for printing large objects.

SLA printing is generally more expensive than FDM printing. The materials used in SLA 3D printing are usually more costly and the process itself is more time consuming. Additionally, SLA 3D printers require more regular maintenance than FDM printers and the parts may need to be replaced more often.

However, SLA 3D printing can produce higher quality prints with finer details and more accurate results. This makes it ideal for creating high-precision parts and prototypes.

SLA (Stereolithography) and STL (Standard Tessellation Language) are two different types of 3D printing technologies. SLA uses a photosensitive liquid resin that is hardened with ultraviolet lasers.

STL, on the other hand, uses fused filament fabrication (FFF) to print 3D objects.

SLA is typically used for high-precision parts and prototypes, while STL is more commonly used for consumer products or hobbyist projects. Both technologies have their advantages and disadvantages, so it is important to choose the one that best suits your needs.

It depends on the project. FDM is often more cost effective and faster, but the prints tend to be of lower quality than those from an SLA 3D printer. On the other hand, SLA prints are more precise and have a higher level of detail, but they can take more time and cost more. It is important to consider the project requirements when choosing between FDM and SLA 3D printing.

SLA printing is usually more expensive than FDM printing. The materials used for SLA are more costly and it takes longer to print. SLA 3D printers require more maintenance than FDM printers, and the parts may need to be changed often. But SLA 3D printing can make higher quality prints with finer details and better results, which makes it good for making high-precision parts.

Yes, SLA 3D printing is usually safe if you do it correctly. Read the instructions and take precautions. Put the printer in an area with some air flow away from anything that can burn. Wear protective gear when you are dealing with the resin and prints.

By following these safety precautions, you can ensure that your SLA 3D printing experience is a safe and successful one.

SLA 3D printing is a great choice for creating high-precision parts and prototypes. It offers detailed results with smooth surfaces and accurate dimensions. SLA 3D printing is also faster than other technologies and can produce complex shapes quickly.

Additionally, the materials used are more cost-effective than other types of 3D printing. All these features make SLA 3D printing a good choice for creating complex objects that require high levels of detail and accuracy.

· SLA printers are good for making precise and detailed parts quickly.

· The materials used in SLA printing usually cost less than other 3D printing technologies.

· All areas of the object can be printed with the same level of accuracy.

· This makes SLA 3D printing a great choice for creating complex parts and prototypes.

· SLA 3D printing is usually more expensive than other 3D printing technologies.

· SLA 3D printers require regular maintenance and the parts may need to be replaced more often.

· The process itself is also time consuming and can take longer than other 3D printing processes.

· Finally, SLA 3D printing is not suitable for large objects or parts with a lot of detail.

SLA prints can degrade over time if exposed to UV light, heat and moisture. To protect your prints, store them in a cool and dry area away from direct sunlight. If you plan to use the prints outdoors, it is best to coat them with UV-resistant spray or resin.

Taking protective measures can help preserve your SLA prints for a longer time.

Yes, there are other 3D printing technologies such as FDM, SLS and MJF. Each one has its own advantages and disadvantages, so it is important to choose the one that best suits your needs. FDM is often more cost effective and faster than SLA, but the prints tend to be of lower quality.

SLS is a powder-based printing technology that offers strong and accurate parts, but it requires more time and maintenance. MJF is a relatively new technology that offers high accuracy and detail but can be more expensive.

It all depends on the project requirements, so it is important to consider all options before choosing the best one.

SLA prints can fail if the printer is not set up properly or if the resin isn’t cured correctly. Additionally, incorrect exposure settings, insufficient ventilation, and dirty or worn-out parts can also lead to failed prints.

To prevent this, always make sure to set up the printer according to the manufacturer’s instructions and keep it clean.

Finally, ensure you are using the right type of resin for your project and follow the curing guidelines carefully.

By following these tips, you can reduce the risk of failed prints.

· SLA printing can cost more money than other 3D printing methods because of the materials, machines, and maintenance.

· SLA printing usually costs more than other types of printing. The printer for the SLA process is also more expensive because it needs to be very precise.

· Additionally, the process itself is time consuming and requires regular maintenance.

· SLA printing can be expensive. But if you need something fast and accurate, SLA printing is a good choice.

SLA printing is faster than FDM. SLA prints require less time to print and the materials used are more cost effective. The process is also more accurate as all areas of the object can be printed with the same level of detail. FDM, on the other hand, tends to take longer and the materials used can be more expensive. It all depends on the project, so it is important to consider both options before making a decision.

In conclusion, SLA printing is a great choice for complex parts and prototypes, but it can also be more expensive than other 3D printing methods. If you need something reliable and accurate, SLA printing is a good option. However, it is important to consider all the pros and cons before deciding which type of 3D printing you should use.

SLA prints are not waterproof on their own. However, they can be protected with a clear coat or other waterproofing material to make them water resistant. This will help protect the prints from water damage and also give them a more polished look. Additionally, make sure to store the prints in a cool and dry place away from direct sunlight to keep them in good condition for a longer tiem.

By following these tips, you can make sure that your SLA prints are protected and will last for a longer time.

One of the biggest problems with 3D printing is that it can be slow and expensive. The time required to print an object depends on the type of printer being used, the materials and complexity of the object, and other factors. Additionally, 3D printing can be more expensive than other manufacturing processes, especially when it comes to large-scale production. It is important to weigh the pros and cons of 3D printing before deciding whether or not it is the right choice.

By considering all the factors, you can make sure that you are investing in the right type of 3D printing for your project.

Yes, SLA prints are generally very strong and durable. The layers of resin used to create the prints are very strong and can withstand a lot of wear and tear. Additionally, some resins are specially designed for strength and durability, which makes them ideal for projects where strength is a priority.

Overall, SLA prints are strong and can be used for a variety of applications. However, it is important to consider the type of resin you are using and the conditions in which the prints will be used to ensure they remain strong for a long time.

PLA and SLA are two different types of 3D printing processes. PLA is a type of plastic filament that melts when heated, whereas SLA uses a liquid resin that is cured with light to harden. PLA prints are usually cheaper and easier to produce, making them a good option for beginners and hobbyists. SLA prints, on the other hand, are more detailed and accurate but also costlier and time-consuming to produce. The type of 3D printing process you choose will depend on the project and your specific needs.

SLA is generally more expensive than SLS because it requires more sophisticated equipment and materials. Additionally, the time and labor involved in producing SLA prints is usually higher than with SLS, making the cost even higher. If budget is a concern and you need a more cost-effective solution, SLS might be the better option.

However, if accuracy and detail are more important than cost savings, then SLA printing is the better choice.

The smallest details that can be printed with SLA depend on the type of printer and material being used. Generally speaking, SLA printers can produce details as small as 0.02mm in size with the right materials and settings.

This makes SLA printers a great choice for producing highly detailed and accurate prints.

The answer to this question depends on the project. SLS is generally more cost-effective and faster than SLA, making it a better option for larger projects. However, SLA is more accurate and produces finer details than SLS, so it can be a better choice for smaller projects that require more intricate details.

SLA prints are generally stronger and more durable than SLS prints. Ultimately, it is important to consider all the factors before deciding which type of 3D printing process is best for your project.

· SLA, DLP, and FDM are all types of 3D printing processes.

· SLA (Stereolithography) uses a liquid resin that is cured with light to harden.

· DLP (Digital Light Processing) uses a digital projector and special UV-sensitive resin to produce prints.

· Finally, FDM (Fused Deposition Modeling) involves the extrusion of molten plastic to build up layers of material.

· Each of these processes has its advantages and disadvantages, so it is important to consider all the factors before deciding which one is best for your project.

SLA printing usually costs more than FDM printing. It needs special equipment and materials, which can be expensive. It also takes longer and more labor to make SLA prints, making them even more costly.

If you want to save money, FDM might be the better option. But if you want something very detailed and accurate, then SLA printing is the best choice.

DLP is usually faster and more cost-effective than SLA since it uses a digital projector instead of the laser used in SLA. DLP also allows for larger prints, as the entire layer can be cured all at once.

Additionally, DLP produces smoother surfaces than SLA and is more suitable for producing complex shapes and designs.

However, SLA produces higher detail than DLP, making it a better choice if accuracy is important.

The best 3D printing method depends on the project and your specific needs. Each of the different technologies, such as SLA, DLP and FDM have their advantages and disadvantages.

It is important to consider all the factors before deciding which one is best for your project. SLA and DLP are best for detailed and accurate prints, while FDM is more suitable for larger projects.

For most projects, SLA and DLP are the best choices, but it is important to consider all your options before making a decision.

Yes, there are three types of SLA 3D printing: laser-based, mask-projection and LCD-based.

Laser-based SLA

Laser-based SLA uses lasers to harden the resin.

Mask-projection SLA

Mask-projection SLA projects light through a mask to selectively harden the material.

LCD-based SLA

LCD-based SLA projects UV light through an LCD panel to harden the resin.

All three types of SLA 3D printing produce highly detailed and accurate prints.

Ultimately, the type you choose should depend on your project and budget. Each of these methods has its advantages and disadvantages, so it is important to consider all the factors before deciding which one is best for your project.

Yes, SLA 3D prints can be very durable depending on the type of material used. If a strong and durable material is used, the prints can be quite resilient to wear and tear. Additionally, SLA printing offers very high detail and accuracy, which can be beneficial for certain projects.

With proper care and maintenance, SLA 3D prints can last a long time.