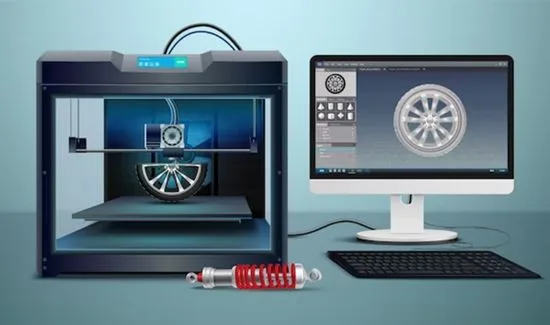

1. What is FDM 3D Printer?

FDM 3D printers are Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF). FDM 3D printer uses thermoplastic material to create three-dimensional objects. They work by heating plastic filaments. Moreover, depositing it layer by layer on a build platform according to the desired shape. The type of 3D printing is common and affordable. It is popular among hobbyists and professionals alike.

1.1. FDM 3D Printer Meaning

FDM stands for Fused Deposition Modeling and is the process by which FDM 3D printers work. Besides, FDM 3D Printers use a filament of thermoplastic material to deposit heat. The FDM printer builds up the model layer-by-layer, creating a 3D object from the ground up. FDM 3D printers are some of the most common and affordable types of 3D printers.2. How Does a FDM 3D Printer Work?

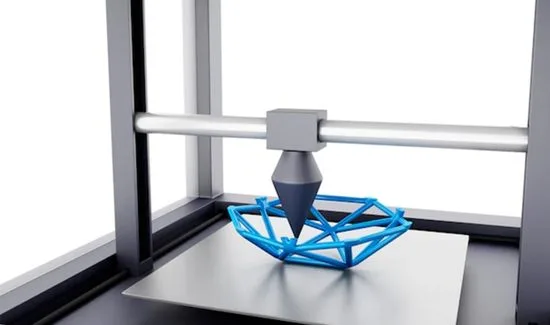

FDM 3D printers process additive manufacturing. Which is adding material to create an object. FDM printers heat thermoplastic material, such as ABS or PLA plastics, in the form of a filament. Even so, this filament is then fed through an extruder head. It helps to move along the axes to deposit the material layer. Moreover, the object will then rise from the bottom until it reaches the desired shape.3. FDM 3D Printer Types

FDM 3D printers come in different sizes. The most common is desktop FDM machines. These desktops can be as small as a few inches tall or large enough to fit on a desk or tabletop. It also has features such as dual extruders. Also comes with heated glass build plates, and enclosed chambers. Above all, FDM 3D printing process is also available in industrial settings. Like, FDM machines are larger and more powerful than their desktop counterparts. These industrial FDM printers are the prototyping and manufacturing of products.4. List down Best FDM 3D Printer

Besides, choose the best FDM 3D printer for your needs. For instance, you should consider the size, and features of the FDM machine, as well as its price. Depending on your budget and goals, it is important to make sure that you are purchasing an FDM 3D printer. That meets all your criteria for printing. Some of the Best FDM 3D Printers are as under:-4.1. Ultimaker S5

The Ultimaker S5 is an FDM 3D printer with a build volume of 330 x 240 x 300 mm. With dual extruders, and a heated glass bed. It has an enclosed chamber for improved temperature control. Which allows for more consistent results in printing.

4.2. Raise3D Pro2 Plus

The Raise3D Pro2 Plus FDM 3D printer has a large build volume of 305 x 305 x 610 mm and supports dual extruders. It has a heated glass bed, and an enclosed chamber for temperature control. One of the features is the filament run-out sensor helps in fine printing.4.3. XYZPrinting da Vinci 1.0 Pro

The XYZPrinting da Vinci 1.0 FDM 3D printer has a build volume of 7.8 x 7.8 x 7.8 inches and supports dual extruders. FDM 3D printer heated aluminum bed for even heat distribution. It has an acrylic chamber for temperature control.4.4. MakerBot Replicator+

The MakerBot Replicator FDM 3D printer has a build volume of 9.9 x 7.8 x 5.9 inches and supports dual extruders. It includes a heated glass bed with an enclosed chamber for temperature control. For fine printing, it has a filament run-out sensor.4.5. Creality Ender 3 Pro

The Creality Ender 3 Pro FDM 3D printer has a build volume of 220 x 220 x 250 mm and supports a single extruder. It includes a heated glass bed with an enclosed chamber for temperature control. For fine printing, it has a filament run-out sensor.4.6. Prusa i3 MK3S+

The Prusa i3 MK3 FDM 3D printer has a build volume of 250 x 210 x 205 mm and supports dual extruders. It includes a heated glass bed with an enclosed chamber for temperature control. For fine printing, it has a filament run-out sensor.4.7. Flashforge Creator Pro

The Flashforge Creator FDM 3D printer has a build volume of 230 x 150 x 140 mm and supports dual extruders. It includes a heated glass bed with an enclosed chamber for temperature control. For fine printing, it has a filament run-out sensor.

4.8. HICTOP Prusa I3 FDM 3D Printer

The HICTOP FDM 3D printer has a build volume of 255 x 250 x 200 mm and supports an extruder. It includes a heated glass bed with an enclosed chamber for temperature control. For fine printing, it has a filament run-out sensor.4.9. Cetus 3D FDM Printer Kit

The Cetus FDM 3D printer has a build volume of 254 x 240 x 200 mm and supports an extruder. It includes a heated glass bed with an enclosed chamber for temperature control. For fine printing, it has a filament run-out sensor. It is important to be sure that the FDM 3D printer you buy is from a reputable manufacturer. Additionally, make sure to read reviews and customer feedback for any FDM 3D printer. So, you are considering purchasing a high-resolution FDM 3d printer – 30.4.10. Fastest FDM 3D Printer

For quick speed, FDM 3D printers have the best features. FDM 3D printer you should look for would be one with a large build area and dual extruders. This will ensure that the FDM 3D printer can print faster and at higher resolutions. Additionally, FDM printers with heated glass beds and enclosed chamber printers. Its filament run-out sensors will help to ensure a smooth printing experience as well. The FDM 3D printers are the fastest in print speed. The Ultimaker S5, Raise3D Pro2 Plus, MakerBot Replicator+, and Prusa i3 MK3S+ are FDM 3D printers. All these FDM 3D printers have large build areas, dual extruders, and heated glass beds.4.11. Largest FDM 3D Printer

The FDM 3D printer with the largest build area is the Raise3D Pro2 Plus FDM 3D printer. It has a build area of 305 x 305 x 610 mm and supports dual extruders. It includes a heated glass bed with an enclosed chamber for temperature control. For fine printing, it has a filament run-out sensor.5. FDM 3D Printer Price Range

The FDM 3D printers that are on the market range models to mid-range to high-end models. Budget FDM 3D comes with one extruder. Mid-range FDM 3D printers have build areas of 250 x 210 x 205 mm or larger with dual extruders. In other words, High-end FDM 3D printers have build areas of 305 x 305 x 610mm. It is larger and can support more than two extruders. The price range for FDM 3D printers will vary depending on the features they offer. Budget FDM 3D printers usually cost less than $500, while mid-range FDM 3D printers range from $500 to $1,000. High-end FDM 3D printers can cost up to $4,000 or more.6. High Resolution FDM 3D Printer

Furthermore, if you’re looking for an FDM 3D printer with the highest possible resolution. Look for one that supports dual extruders and has a heated glass bed. TheUltimaker S5 and Raise3D Pro2 Plus FDM 3D are the highest print resolution printers. FDM includes a heated glass bed with an enclosed chamber for temperature control. For fine printing, it has a filament run-out sensor.

7. FDM 3D Printer Kit

FDM 3D printer kits are a great way to get started with FDM 3D printing. These kits come with all the parts and components you need to assemble. In other words, kits models for mid-range and high-end FDM 3D printers. The FDM 3D printer kits that are currently available range in price from less than $200 to more than $1,000. Budget FDM 3D printer kits usually come with smaller build areas and one extruder. While mid-range FDM 3D printer kits have larger build areas and dual extruders. High-end FDM 3D printer kits usually have the largest build areas with many extruders.8. FDM 3D Printing Regulations

It is important to note that FDM 3D printing can come with some regulations. Above all, FDM 3D printers are well-ventilated areas. Because the thermoplastic material can emit fumes. It’s particles that may be hazardous to your health. Yet, it should be used by an adult who knows how to use it. It is necessary to have the experience to use it.9. FDM 3D Printer File Format

Following, FDM 3D Printer files using a CAD program. They can be in various file formats, such as STL, OBJ, WRL, and more. Make sure to check the specifications of your 3D Printer. Make sure that it is compatible with the file format you plan to use.10. Conclusion

Also, FDM 3D printers are one of the most popular types of 3D printing technology available today. So, they are becoming popular for industrial applications as well as home use. But also, FDM machines come in a variety of sizes and offers. FDM 3D printer-50 features and capabilities to fit your needs and budget. No matter what your FDM 3D printing goals are. Always be sure that there is an FDM 3D printer out there that will best meet your needs. We hope that this article has provided you with an overview of FDM 3D printers and what they have to offer. With a variety of FDM 3D printer types on the market, it can be hard to know which one is best for you. Considering the size, features, capabilities, and applications of FDM 3D printers in your needs. So, now that you know a little bit more about FDM 3D printers, why not take the plunge and get one? Whether it’s for your business or to have some fun at home, FDM 3D printing can open up a whole new world of possibilities. So, what are you waiting for? Get FDM 3D printing today!FAQs

Disadvantages of FDM The main disadvantage of FDM 3D printing is the limited resolution and detail that can be achieved. Additionally, FDM 3D printers require upkeep, such as nozzle replacements and filament purchases, which can add up over time. Finally, some materials are more difficult to print than others and may require advanced printer settings or additional support structures.

FDM 3D printers typically work with plastic materials such as ABS, PLA, TPU, and PETG. However, other materials such as wood and metal filaments can also be used with some FDM 3D printers. It is important to check the specifications of your printer before purchasing materials, as some filaments may not be compatible with it. It is also worth noting that some materials can be harder to print than others, so it is important to consider your experience level and the complexity of the project before selecting a material. Understanding the properties of each material and how it behaves when printed can help you select the right one for your project.

FDM 3D printing is more affordable than other types of 3D printing, making it one of the most popular options for individuals and small businesses. The cost of materials and the printer itself are lower, although consumables such as filament may need to be replaced occasionally. In general, FDM 3D printing is a more cost-effective option than other technologies.

FDM 3D printers are capable of printing with a variety of materials, including plastics such as ABS, PLA and PETG; metals such as stainless steel and aluminum; ceramics such as porcelain and clay; and composites such as wood-filled PLA. In addition, FDM 3D printers can be used to print with a variety of filaments and other materials. The specific material that can be used depends on the printer model.

The type of 3D printing that is right for you depends on your needs. FDM printing offers a lower cost and shorter lead time, but the resolution and surface finish of the prints may not be as good as those from SLA printing. On the other hand, SLA printing offers higher resolution and better surface finish, but at a higher cost and with longer lead times. It is important to consider your specific needs before making a decision.

Yes, a FDM 3D printer can be used by a 5th grader, although some supervision may be required. FDM 3D printers are relatively easy to use and can be configured to print with various materials and settings. However, some knowledge of 3D printing is recommended before attempting to use an FDM 3D printer.

The main disadvantage of FDM 3D printing is that it can produce lower resolution and poorer surface finish than other types of 3D printing. Additionally, FDM 3D printers require more maintenance than other types of 3D printers, as the nozzle and extruder need to be cleaned periodically. Finally, FDM 3D printers are generally slower than other types of 3D printers. Overall, FDM 3D printing is a good option for individuals and small businesses who need to produce prototypes or small batches of parts quickly and at a lower cost.

Resin prints are generally stronger than FDM prints, as they are printed with a liquid resin that is cured using ultraviolet light. This results in a stronger and more durable print than FDM printing, which relies on heated plastic filament. However, resin prints are also typically more expensive and time consuming to produce than FDM prints. Additionally, resin prints have a higher risk of failure due to the need for UV light and specialized resins. Therefore, it is important to consider your needs before deciding which type of 3D printing is best for you.

FDM 3D printing is popular due to its affordability, relative ease of use, and wide range of materials that can be used. It is a great option for individuals and small businesses who need to quickly produce prototypes or small batches of parts. Additionally, FDM 3D printers are widely available and can be purchased for a relatively low cost.

Yes, the Ender 3 is an FDM 3D printer. It is a popular choice for those looking to get into 3D printing because it is affordable, easy to use, and has great print quality. It is also compatible with many different materials and filaments, making it a great option for a variety of applications.

FDM (fused deposition modeling) is a 3D printing technology that uses melted plastic filament to create objects. PLA, or polylactic acid, is a specific type of plastic material that is commonly used in FDM 3D printing. Therefore, the difference between FDM and PLA is that FDM is a 3D printing technology, while PLA is one of the materials that can be used with this technology. Another difference between FDM and PLA is that PLA is biodegradable, while FDM prints are generally not. The choice between these two technologies depends on your needs, as FDM offers lower cost and shorter lead times, while PLA provides higher resolution and better surface finish. It is important to consider your specific needs before making a decision. Can I use an FDM 3D printer for production? Yes, an FDM 3D printer can be used for production, depending on your needs. FDM 3D printers are a great option for producing prototypes and small batches of parts quickly and at a lower cost. Additionally, FDM 3D printers are widely available and can be configured to print with various materials. However, it is important to consider the resolution, surface finish and lead time of your specific project before deciding whether an FDM 3D printer is the best option for production.

No, FDM 3D printers are limited to printing with plastic filaments. If you need to create metal parts, you will need to use a different type of 3D printing technology, such as metal laser sintering or direct metal laser melting. However, FDM 3D printing is a great option for producing prototypes or small batches of plastic parts quickly and cost-effectively.

FDM 3D printing has some downsides. It produces lower quality pictures than other 3D printing methods, takes longer to make things, and you can only use a few materials. You can only use plastic filaments with FDM 3D printing so it won’t work for metals or other materials. Think about what you need before deciding if this is the right choice for you.

Yes, there are safety concerns with FDM 3D printing. Because the process involves melting plastic filaments, it can generate a significant amount of heat and fumes. It is important to ensure that the area you are printing in is well-ventilated and that you are wearing proper safety equipment, such as a face mask and gloves. Additionally, you should always follow the instructions provided by your 3D printer to ensure safe operation.

The strongest form of 3D printing is metal laser sintering (MLS) or direct metal laser melting (DMLM). These processes use lasers to melt metal powder or wire, resulting in parts with extremely high strength and durability. Additionally, these processes can produce complex geometries that would not be possible with traditional manufacturing methods. However, these processes are also more expensive and require specialized knowledge to operate. Therefore, it is important to consider your specific needs before deciding which 3D printing process is best for you.

It depends on the project and your needs. FDM 3D printing is a great option for producing prototypes quickly and cost-effectively. Additionally, it can be used to produce small batches of parts with complex geometries that would not be possible with traditional manufacturing methods. However, FDM 3D printing is limited to producing parts with lower resolution and surface finish than traditional manufacturing methods. Therefore, it is important to consider your specific needs before deciding which option is best for your project.

Yes, PLA filament is one of the most commonly used materials with FDM 3D printers. It has good layer adhesion and relatively low shrinkage, making it a great option for producing prototypes and small batches of parts quickly and cost-effectively. Additionally, PLA filament is widely available and comes in a variety of colors. However, it is important to consider the resolution and surface finish of your specific project before deciding on which material to use.

Printing with PLA filament is usually easier than printing with ABS filament. PLA has better adhesion and shrinking, so it is easier to use. Think about the resolution and surface finish of your project before choosing a material. ABS may be better if you need higher resolution or a smoother finish. ABS also holds up better in hot temperatures than PLA, which can be helpful for some projects.

FDM 3D printing is a great option for producing prototypes or small batches of parts quickly and cost-effectively. It can be used to produce complex geometries that are not possible with traditional manufacturing methods. Additionally, FDM 3D printing is widely accessible and there are many materials available to choose from. Consider your specific needs before deciding which 3D printing process is best for you.

Yes, many materials used in FDM 3D printing can be recycled. PLA and PETG filaments are two of the most commonly used materials and both can be recycled in certain facilities. Additionally, some companies have developed processes to recycle ABS filaments as well. Be sure to follow local regulations when disposing of 3D printing materials.

FDM (fused deposition modeling) and FFF (fused filament fabrication) 3D printing are both term used to describe the same process. FDM 3D printing is the most common type of 3D printing and involves extruding melted plastic filament through a nozzle to build up layers of material. FFF 3D printing is a term often used to differentiate this process from other types of 3D printing such as SLA, SLS, and DLP. Both terms are generally interchangeable, but FFF is sometimes used to refer specifically to FDM 3D printing that uses plastic filaments. No matter which term you choose to use, they both generally refer to the same process.

FDM 3D printing has some disadvantages. The parts it makes are not as good quality as parts made with traditional methods. They might be weaker or more breakable too. Think about this before deciding to use FDM 3D printing for your project. FDM 3D printing takes a long time because it needs to print many layers. Also, most FDM 3D printers can only make small parts. If you want to make something big, you have to print several pieces and put them together. FDM 3D printing may cost more than other types of 3D printing. This is because it requires special equipment and materials to do the printing. Think about all these things before deciding if FDM 3D printing is the right choice for your project.

Yes, the Ender 3 is an FFF (fused filament fabrication) printer. It uses a heated nozzle to melt and extrude plastic filament, layer by layer, to build up 3D objects. The Ender 3 is a popular choice for beginners as it is relatively affordable and has a good reputation for reliability. It is important to remember that FFF and FDM are terms used interchangeably to refer to the same process of 3D printing.

The maximum resolution of an FDM 3D printer depends on the printer and the materials used. Generally, high-end FDM 3D printers can achieve layer heights as low as 0.05mm. However, the resolution of an FDM 3D printer is limited by the size of the nozzle and the material being used. For example, a finer nozzle may be able to produce a higher resolution, but the filament material must also be able to flow through it for it to work.

The cost of FDM 3D printing depends on the printer, materials used, and other factors. Generally, it is more affordable than traditional manufacturing methods, but it can still be expensive depending on the size and complexity of your project. Additionally, maintenance costs such as nozzle replacements and filament purchases can add up over time.

FDM 3D printing is popular for a few reasons. It’s relatively easy to learn and use, it has a wide range of compatible materials, and it can produce parts quickly and cheaply. Another advantage is that FDM 3D printers are relatively affordable compared to other types of 3D printers. This makes them accessible to small businesses, hobbyists, and makerspaces. Finally, FDM 3D printers are known for their reliability and are capable of producing high-quality parts. This makes them a great choice for prototyping or small-scale production.